The Story of Bungay Butter

What’s that monument on the front of our Bungay Butter boxes? It’s a good story actually. Pull up a cushion…

It’s a buttercross. Historically, buttercrosses were beautiful vaulted structures, beneath which local farmers would congregate to sell their wares, including butter and cheese.

You see, around 300 years ago, Suffolk was famous for its butter. Every foodie worth their weight in grouse was eating Suffolk butter. It was sold into the finest houses in London and shipped in barrels to the West Indies.

But the Suffolk farmers had a problem. They had no way to use the skimmed milk left over after buttermaking, so they began to make a hard skimmed milk cheese, to recoup some cash from the waste milk.

The cheese was named the Suffolk Bang. Legend has it that this was the worst cheese ever made in the history of British cheese. It was so bad that poems were written about it. Allegedly it was “so hard that you could roll cannons on it” and “dogs would bark at it but would not dare bite it”. It was sold to the British Navy because the weavils couldn’t get into it, but the sailors threatened mutiny rather than eat the awful Suffolk Bang. Eventually, the Suffolk farmers were ordered by the government to stop making it, as it was giving the nation a bad name. And so, Suffolk cheese production ceased and with it, butter production folded too.

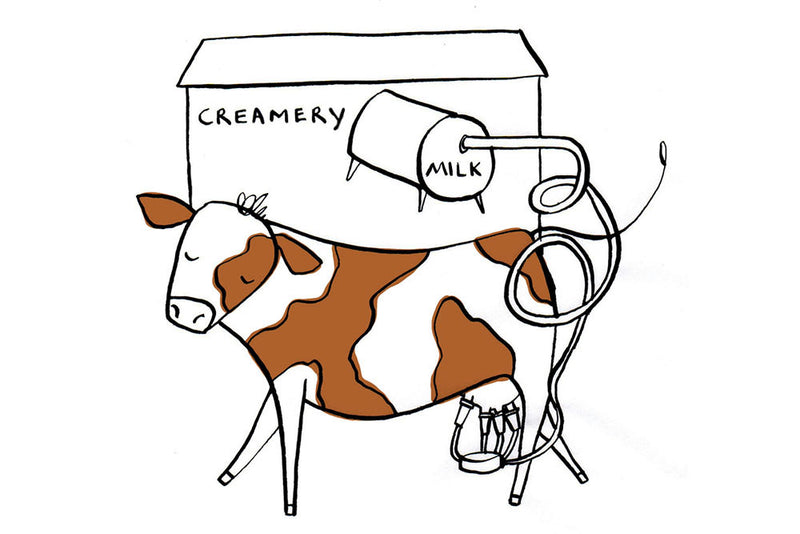

The famous Suffolk Butter was lost to the years and never a scrape of butter was to be found under the buttercross for close to 300 years… until now.

Bungay Butter is our way of attempting to restore the name of Suffolk Butter. It is made to an ancient recipe, with our raw cultured cream. As far as we know, this is very close to the way it would have been made in the heyday of Suffolk butter production, 300 years ago.